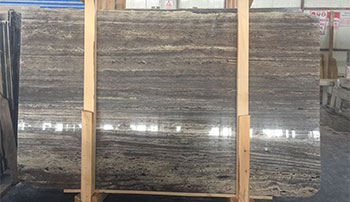

SILVER TRAVERTINE

Selection that adds value to the projects with its natural appearance favored by architects used in many projects today. Particularly, veins are seen horizontally, and primary selection can be done in line with the veins, and it comes to the forefront with its natural appearance. Iran Silver Travertine and Turkish Silver Travertine are also available in marble quarries of both countries and these selection projects can be supplied as polished slab, cut-to-size material and blocks. The Silver Traverten is located in a luxurious use area, especially in projects where the brown appearance of the wood with the light gray entrances is visible. This selections, which are used as high-end items in special usage areas such as business centers, hospitals, hotels and villas, can be used with other types of natural to ensure the integrity of the project.

Iran selections are recognized all over the world. Blocks extracted from quarries located in Iran are processed in factories either in the environmental factories or in Turkey. Projects are usually available in 2 cm polished slabs as requested but also Silver Travertine projects can based on cut-to-size material or blasting this products. Iran has a very efficient range and variety in terms of reserves. Silver traverten production, which is demanded in international projects with high metric, is continuously produced in productive quarries. One of the issues to be considered in purchasing natural is to take the blocks of the same quarry throughout the entire project. Even with the same travertine selection, the color or tone differs between the blocks of different quarries. The same selection for the integrity of the project and the supplying of stone from one quarry during the projects are important.

This quarries located in Central Anatolia in Turkey have been producing for big projects for years. The natural stone industry is very old in Turkey and the leading companies in the industry are producing polished slabs and cut-to-size materials for travertine production for many years. The selection of Turkish silver is somewhat lighter than that of Iranian stones. Types of material which are divided into the selections within itself and they are also frequently preferred in boutique projects. Parts of low quality selections are given as cheap materials to other factory or internal market for split face or mosaic production. First class products are generally exported to projects abroad.

The domestic sales of the materials produced in Turkey are made from our factory, and our international sales are made to İzmir, Gebze and Mersin ports all over the world. Silver natural products transport to Middle East countries and Turkic Republics are mostly done by road because of proximity. Requests made on a project basis are offered to you as a special price for the size of the project and the selection of the desired quality of the this stone. Generally used dimensions in projects according to price/performance ratio are 3x40x80 cm in the claddings and 2x60x60 cm in the floorings. If larger sizes are required, price work is done according to the wastage rate. This selections can be used as different surface treatments according to the needs of the projects. In general, polished materials can be treated as honing, sanding and hammering. Polished surface is not recommended for application projects that will be used as outdoor flooring.

SILVER TRAVERTINE PRICES

Prices may vary depending on the quality, size and selection of the this requested. Iranian Silver Travertine varieties are generally sold at more affordable prices due to the reasonably priced raw material. On average, 2 cm polished slab prices range from $ 35 / sqm to $ 50 / sqm. Due to the low selection or quality of the selection is available in the sector at more affordable prices.

First-class traverten types are offered as priority in overseas projects. In the domestic market, second-class or high-quality selection of non-vein structures is offered to projects for affordable product requests. For the this stone, which have water veins, the vein following is a very important pricing feature. The pricing for the projects is made specifically for our factory and for the selection of the requested travertine.

IRAN SILVER TRAVERTINE

The selection with dark and light brown vein structure is called Titanium Silver Travertine.In the production; Turkey and Iran are the countries in the forefront.With regard to exports to America and Arab countries; work has been going on for many years.While the extracted lighter shades in Turkey whereas the varieties extracted from the quarries in Iran are clearly seen as darker and brownish.Because of the fact that Iran Silver stone is more aware all over the world; production is the foreground.Blocks with various vein structures removed from many quarters are processed in fabrics and prepared as slab and cut-to-size materials.

Project-based requests are made by determining the appropriate this and quality control is carried out at the factory prior to the crating process, preventing low quality from entering the project.Because of the deterioration of production vein structure or unwanted movements made from first class blocks, some parts are separated in the process of processing.Since the appearance of the vein structure in the silver traverten varieties adds an extra decorative appearance, most of the block cut is made in vein-cut.Since the structure of the horizontal vein is clearly visible, integrity is ensured by performing veinl alignment in the application areas.

The vein structures and color tones of blocks extracted from different quarries are not the same as each other.It is important to study from a single quarry in high-volume project application works.It is preferred because it is convenient and decorative in many projects demanded by architectural offices.Along with light gray shades, other natural types can be worked in harmony. The silver travertine varieties, which find themselves in application areas such as exterior cladding and interior wall covering, are continuously processed in factories and kept as 2 cm polished slab and cut-to-size materials as stock.The application areas prepared from the first class stones create a quality presentation by adding extra value to the projects.

APPLICATION AREAS OF SILVER TRAVERTINE

Luxurious hotels, business centers and villas are often preferred in areas where visibility is at a premium.Stones that can be used for interior wall covering and special designs, which provide integrity to the application area due to their dark tones; can also be furnished with white marble varieties.Due to its structure, it is not suitable for areas such as countertops, vanities and tables.Silver travertine with suitable hardness for cladding areas; can be used as 2 cm thickness with filledand polished.

It is more appropriate to visualize the use of horizontal vein structure in dark selections.High quality is preferred in luxury constructions and is the mainstay of the application area.Titanium travertine is preferred in luxury buildings with high-quantity materials and is the main stone of the application area.Application of cross-cutsotnes which is suitable for use as exterior cladding in 3 cm thickness and 40x80 cm dimensions maintain its durability for many years.Because of its lighter specific weight compared to other marble types is seen as an advantage to place the building load on the exterior cladding operations.In countries where the temperature is high, the choice of light colors is more appropriate in terms of heat insulation. In facade application projects; 3 cm thickness is recommended due to weather conditions.Apart from polished surface treatment in the outdoor flooring areas, sandblasting, honing and hammering operations can be done.It is used in many projects due to its natural and decorative appearance.

SPECIFICATIONS OF SILVER TRAVERTINE

There are two different views in light gray and dark brown tones.Due to their properties, there are small holes on the raw slabs.During the cutting, according to the necessity, the filling process is carried out according to the selection of the stone and integrity is ensured.The high quality of the finishes and materials of the machines in the factories increases the total quality of the work.Due to its fine crystalline structure, the dough structure is not clear as long as it is not closely watched, so it gives a good visual result in application areas.

Clear and dark horizontal (vein-cut) cutting operations are performed to ensure the appearance of the vein.Silver Travertine is appreciated by architectural offices for its visibility due to its vein structure.In areas such as exterior cladding and outdoor flooring, crosscut is preferred.Due to the application of epoxy net, 2 cm thick travertine suitable for use; can be used in large sizes due to its durability. Our sales are done from our factory on project basis or slab basis. Production is made for the requests coming from abroad are exported from the ports as containers. After the planning made for the production of special demands, requests other than slabs such as raw travertine, billets, mosaics, blasting are also met. Our production and sales of high-quality stone are carried out in a factory by supplying raw materials in a planned way. Blocks are supplied from the quarries in accordance with the selection of the material to be used in the project.

SILVER TRAVERTINE PRODUCTION AND EXPORT

Blocks extracted from quarries in Iran are processed in factories and prepared as 2 cm slab and cut-to-size materials.Since a large majority of market requirements are 2 cm polished silver travertine, production in factories is continuous.Project-based requests are prepared in slab and cut-to-size according to the determined variety.Due to the fact that the quarries are efficient, the production of high quality is continuously performed.Due to the inefficiency of the quarries during the winter months, necessary block stocks are made in the factory in the summer months.Standard dimensions: 2x30x60 cm and 2x60x60 cm are in the foreground.They are the most recommended sizes for flooring applications in terms of price / performance.Small pieces or low quality materials produced during production are sent to mosaics and split-face factories for production of decorative products.

Productions made in the Iranian plant can be exported on the port of Bandar Abbas.Because of the quality control and close proximity; Mersin port can also be used for export.Selections that are frequently preferred by luxury constructions such as hotels and business centers with high-value application area are prepared in export quality and crated It is ensured that the most suitable stones are sent by carrying out quality control at the factory just before the export operations.For the cutting process in Turkey; block can be bring from Iran.Iran Silver Travertine production is relatively easy compared to other types of marble and because of high sales opportunities, it has been working intensively for many years.Due to the high quality production of mosaic and split-face in Turkey; the production is processed in different patterns by introducing more parts or debris.The products we sell to the Turkic Republics are made by road.

BLOCK SALES

Block sales made by marking from quarry are realized to large marble manufacturer firms or sculpture processing firms.The quality control is done before blocks came out of quarry in order to prevent unwanted selections are made to be exported.Iran has different color tones in the quarries and it is necessary to make block purchases by determining the quarry according to the type suitable for the project.

Silver Traverten Block Sales are made from the quarries on ton basis.Export quality blocks are marked by produced blocks; production planning for higher demands is made according to seasonal conditions and new blocks are provided.The vast majority of block sales are made to China and India.Turkey imports blocks for its own domestic demand and export to United States and Arap markets. Due to its homogeneous structure and natural appearance; the production and processing of the selection which is in high demand is carried out by many factories in Turkey.